Bourbons and Distillers

Four Roses Distillery — Lawrenceburg, Kentucky

Heaven Hill Distillery, Bardstown, Kentucky

Buffalo Trace Distillery — Frankfort, Kentucky

Jim Beam Distilleries, Clermont, Kentucky

Woodford Reserve Distillery — Versailles, Kentucky

Tom Moore - Bardstown, Kentucky

Maker's Mark Distillery — Loretto, Kentucky

Wild Turkey Distillery — Lawrenceburg, Kentucky

A platform for the connoisseurs to indulge with the mesmerizing beverages and lip smacking global cuisines, access the information and review and interact at the same time. This is also a huge support tool for the Hospitality aspirants pursuing any Hotel Management Program or is a beginner with the Hospitality Industry.

Amazon

Monday, March 14, 2011

BRANDS

American Corn Whiskeys

Catdaddy

Mountain Moonshine

Old Gristmill

Old Oak

Virginia Lightning

Georgia Moon

Dixie Dew

Mellow Corn

J.W. Corn

Platte Valley

Catdaddy

Mountain Moonshine

Old Gristmill

Old Oak

Virginia Lightning

Georgia Moon

Dixie Dew

Mellow Corn

J.W. Corn

Platte Valley

BRANDS

American Single Malt Whiskeys

Charbay

McCarthy's

Notch

Peregrine Rock

St. George

RoughStock

Stranahan's

Wasmund's

Woodstone Creek

Gold Buckle Club - The Ellensburg Distillery, Ellensburg, Washington

Charbay

McCarthy's

Notch

Peregrine Rock

St. George

RoughStock

Stranahan's

Wasmund's

Woodstone Creek

Gold Buckle Club - The Ellensburg Distillery, Ellensburg, Washington

Saturday, March 12, 2011

WINE TERMINOLOGY

Acidity

The presence of natural fruit acids that lend a tart, crisp taste to wine

Aroma

Smells in wine that originate from the grape

Astringent

Bitter; gives a drying sensation in the mouth

Balanced

All components of the wine are in harmony

Barrel Fermented

White wine that is fermented in an oak barrel instead of a stainless steel tank

Body

The weight and tactile impression of the wine on the palate that ranges from light to heavy/full

Bouquet

Smells from winemaking, aging and bottle age

Buttery

Rich, creamy flavor associated with barrel fermentation

Character

Describes distinct attributes of a wine

Chewy

Wine that has a very deep, textured and mouth-filling sensation

Clean

Wine without disagreeable aromas or tastes

Closed

Wine that needs to open up; aging and/or decanting can help

Complex

Layered aromas, flavors and textures

Cooked

Wine that has been exposed to excessively high temperatures; spoiled

Corked

Wine that has been tainted with moldy smells or other obvious flaws from a bad cork

Delicate

Light, soft and fresh wine

Dry

No sugar or sweetness remaining; a fruity wine can be dry

Earthy

Flavors and aromas of mushroom, soil and mineral

Elegance

A well balanced, full wine with pleasant, distinct character

Finish

The final impression of a wine on the palate; ranges from short to long

Firm

Texture and structure of a young, tannic red

Flabby/Flat

Lacking in acidity, mouth-feel, structure and/or texture

Fleshy

A soft textured wine

Flinty

A mineral tone, aroma or flavor

Floral

Flower aromas such as rose petals, violets, gardenia or honeysuckle

Fruity

Obvious fruit aromas and flavors; not to be confused with sweet flavors such as berries, cherries and citrus

Full-Bodied

Rich, mouth filling, weighty-textured wine

Grassy

Aromas and flavors of fresh cut grass or fresh herbs

Green

Unripe, tart flavors

Hard

Texture and structure that hinders flavor

Herbaceous

Grassy, vegetable tones and aromas

Lean

Wine is thin and tastes more acidic than fruity

Legs

Teardrop impressions of alcohol weightiness that are visible on the inside edges of a wine glass

Light-Bodied

A wine with delicate flavors, texture and aromas

Lively

Young, fruity and vivacious flavor

Malolactic

Conversion of hard, malic acid (green apple flavors) in wine to soft, lactic acid (rich, butter flavors)

Medium-Bodied

A wine with solid, but not rich weight and texture

Nose

The smell of a wine; aroma

Oak

Aromas and flavors contributed during barrel fermentation and/or aging such as vanilla, caramel, chocolate, smoke, spice or toast

Off-Dry (Semi-dry)

Very low levels of residual sugar remaining in the wine

Rich

Weighty flavors and texture

Round

Smooth flavors and texture; well-balanced

Smoky/Toasty

Aromas of smoke and toast imparted by fired barrels

Sweet

Wines that have a higher concentration of sugar after fermentation

Tannin

A drying, astringent sensation on the palate that is generally associated with heavier red wines

Terroir

French word reflecting the expression of soil, topography and climate in a wine

Thin

Wine is unpleasantly watery and lacks flavor and texture

Vegetal

Herbal, weedy aromas and flavors

Velvety

Smooth-textured with deep, rich aromas and flavors

Vintage

Year that grapes were harvested and fermented to make a wine

The presence of natural fruit acids that lend a tart, crisp taste to wine

Aroma

Smells in wine that originate from the grape

Astringent

Bitter; gives a drying sensation in the mouth

Balanced

All components of the wine are in harmony

Barrel Fermented

White wine that is fermented in an oak barrel instead of a stainless steel tank

Body

The weight and tactile impression of the wine on the palate that ranges from light to heavy/full

Bouquet

Smells from winemaking, aging and bottle age

Buttery

Rich, creamy flavor associated with barrel fermentation

Character

Describes distinct attributes of a wine

Chewy

Wine that has a very deep, textured and mouth-filling sensation

Clean

Wine without disagreeable aromas or tastes

Closed

Wine that needs to open up; aging and/or decanting can help

Complex

Layered aromas, flavors and textures

Cooked

Wine that has been exposed to excessively high temperatures; spoiled

Corked

Wine that has been tainted with moldy smells or other obvious flaws from a bad cork

Delicate

Light, soft and fresh wine

Dry

No sugar or sweetness remaining; a fruity wine can be dry

Earthy

Flavors and aromas of mushroom, soil and mineral

Elegance

A well balanced, full wine with pleasant, distinct character

Finish

The final impression of a wine on the palate; ranges from short to long

Firm

Texture and structure of a young, tannic red

Flabby/Flat

Lacking in acidity, mouth-feel, structure and/or texture

Fleshy

A soft textured wine

Flinty

A mineral tone, aroma or flavor

Floral

Flower aromas such as rose petals, violets, gardenia or honeysuckle

Fruity

Obvious fruit aromas and flavors; not to be confused with sweet flavors such as berries, cherries and citrus

Full-Bodied

Rich, mouth filling, weighty-textured wine

Grassy

Aromas and flavors of fresh cut grass or fresh herbs

Green

Unripe, tart flavors

Hard

Texture and structure that hinders flavor

Herbaceous

Grassy, vegetable tones and aromas

Lean

Wine is thin and tastes more acidic than fruity

Legs

Teardrop impressions of alcohol weightiness that are visible on the inside edges of a wine glass

Light-Bodied

A wine with delicate flavors, texture and aromas

Lively

Young, fruity and vivacious flavor

Malolactic

Conversion of hard, malic acid (green apple flavors) in wine to soft, lactic acid (rich, butter flavors)

Medium-Bodied

A wine with solid, but not rich weight and texture

Nose

The smell of a wine; aroma

Oak

Aromas and flavors contributed during barrel fermentation and/or aging such as vanilla, caramel, chocolate, smoke, spice or toast

Off-Dry (Semi-dry)

Very low levels of residual sugar remaining in the wine

Rich

Weighty flavors and texture

Round

Smooth flavors and texture; well-balanced

Smoky/Toasty

Aromas of smoke and toast imparted by fired barrels

Sweet

Wines that have a higher concentration of sugar after fermentation

Tannin

A drying, astringent sensation on the palate that is generally associated with heavier red wines

Terroir

French word reflecting the expression of soil, topography and climate in a wine

Thin

Wine is unpleasantly watery and lacks flavor and texture

Vegetal

Herbal, weedy aromas and flavors

Velvety

Smooth-textured with deep, rich aromas and flavors

Vintage

Year that grapes were harvested and fermented to make a wine

Tuesday, March 8, 2011

TYPES OF BEER

Lager

The word lager is derived from the German verb “lagern”, which means: to store. During the late middle ages, before the days of refrigeration, fermentation was a hit-or-miss affair, especially during the hot summer months. To ensure a supply of beer for the summer, brewers in the Bavarian Alps stored kegs of spring brew in icy mountain caves. As the beer slowly aged, the yeast settled, creating a drink that was dark but clear and sparkling with a crisper, more delicate flavour. In 1842, lager acquired its familiar golden colour when a brewery in Pilsen, Czechoslovakia perfected a pale, bottom-fermented version of the beer. Lagers typically take more time to brew and are aged longer than ales. Lagers are best enjoyed at cooler-than-room temperature.

Bock Beer

The other bottom-fermented beer is bock, named for the famous medieval German brewing town of Einbeck. Heavier than lager and darkened by high-coloured malts, bock is traditionally brewed in the winter for drinking during the spring.

Ale

Although the term covers a fascinating variety of styles, all ales share certain characteristics. Top-fermentation and the inclusion of more hops in the wort gives these beers a distinctive fruitiness, acidity and a pleasantly-bitter seasoning. All ales typically take less time to brew and age then lagers and have a more assertive, individual personality, though their alcoholic strength may be the same. Ales are best enjoyed at room temperature or slightly warmer.

Porter and Stout

Whether dry or sweet, flavoured with roasted malt barley, oats or certain sugars, stouts and porters are characterized by darkness and depth. Both types of beer are delicious with hearty meat stews and surprisingly good with shellfish. The pairing of oysters and stout has long been acknowledged as one of the world's great gastronomic marriages.

Dry

“Dry” refers to the amount of residual sugar left in a beer following fermentation. This type of beer is fermented for longer than normal brews so that practically all of the residual sugar is converted into alcohol. The result is a beer which consumers describe as having a crisp flavour, clean finish and very little aftertaste.

The word lager is derived from the German verb “lagern”, which means: to store. During the late middle ages, before the days of refrigeration, fermentation was a hit-or-miss affair, especially during the hot summer months. To ensure a supply of beer for the summer, brewers in the Bavarian Alps stored kegs of spring brew in icy mountain caves. As the beer slowly aged, the yeast settled, creating a drink that was dark but clear and sparkling with a crisper, more delicate flavour. In 1842, lager acquired its familiar golden colour when a brewery in Pilsen, Czechoslovakia perfected a pale, bottom-fermented version of the beer. Lagers typically take more time to brew and are aged longer than ales. Lagers are best enjoyed at cooler-than-room temperature.

Bock Beer

The other bottom-fermented beer is bock, named for the famous medieval German brewing town of Einbeck. Heavier than lager and darkened by high-coloured malts, bock is traditionally brewed in the winter for drinking during the spring.

Ale

Although the term covers a fascinating variety of styles, all ales share certain characteristics. Top-fermentation and the inclusion of more hops in the wort gives these beers a distinctive fruitiness, acidity and a pleasantly-bitter seasoning. All ales typically take less time to brew and age then lagers and have a more assertive, individual personality, though their alcoholic strength may be the same. Ales are best enjoyed at room temperature or slightly warmer.

Porter and Stout

Whether dry or sweet, flavoured with roasted malt barley, oats or certain sugars, stouts and porters are characterized by darkness and depth. Both types of beer are delicious with hearty meat stews and surprisingly good with shellfish. The pairing of oysters and stout has long been acknowledged as one of the world's great gastronomic marriages.

Dry

“Dry” refers to the amount of residual sugar left in a beer following fermentation. This type of beer is fermented for longer than normal brews so that practically all of the residual sugar is converted into alcohol. The result is a beer which consumers describe as having a crisp flavour, clean finish and very little aftertaste.

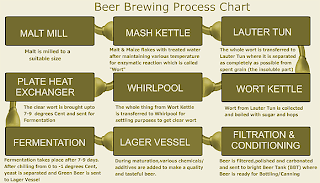

MAKING OF BEER

Brewing is fundamentally a natural process. The art and science of brewing lies in converting natural food materials into a pure, pleasing beverage. Although great strides have been made with the techniques for achieving high-quality production, beer today is still a beverage brewed from natural products in a traditional way. Although the main ingredients of beer have remained constant (water, yeast, malt and hops), it is the precise recipe and timing of the brew that gives one a different taste from another. The production of beer is one of the most closely supervised and controlled manufacturing processes in our society. Apart from brewing company expenditures on research and quality control designed to achieve the highest standards of uniformity and purity in the product, the production of beer is also subject to regular inspection and review by federal and provincial Health Departments. Substances used in the brewing process are approved by Health Canada. On average, a batch of beer will take about 30 days to produce. To be more specific, brewing takes nine and a half hours, while fermentation and aging combined take between 21 and 35 days for ales and lagers respectively.

1.Water

Pure water is an essential ingredient in good beer and brewers pay scrupulous attention to the source and purification of their brewing water. The water used in brewing is purified to rigidly-set standards. If it does not have the proper calcium or acidic content for maximum activity of the enzymes in the mash, it must be brought up to that standard.

2.Malt

Barley is used to make brewers' malt. At the malting companies, barley is soaked, germinated (sprouted), then dried and/or kilned/roasted to arrest further growth. During the period of controlled growth in the malting plant, specific barley enzymes are released to break down the membranes of the starch cells that make up most of the kernel. But these are internal changes only; apart from a slight change in colour, the external characteristics remain essentially unchanged. When the malt leaves a malting plant, it still looks like barley.

In the brewery, the malt is screened and crushed rather than ground to flour in order to keep the husks as whole as possible. This process not only prevents the extraction of undesirable materials from the husks but also allows them to act as a filter bed for separation of the liquid extract formed during mashing.

3.Mashing

Malt is added to heated, purified water and, through a carefully controlled time and temperature process, the malt enzymes break down the starch to sugar and the complex proteins of the malt to simpler nitrogen compounds. Mashing takes place in a large, round tank called a "mash mixer" or "mash tun" and requires careful temperature control. At this point, depending on the type of beer desired, the malt is supplemented by starch from other cereals such as corn, wheat or rice.

4.Lautering

The mash is transferred to a straining (or lautering) vessel which is usually cylindrical with a slotted false bottom two to five centimetres above the true bottom. The liquid extract drains through the false bottom and is run off to the brew kettle. This extract, a sugar solution, is called "wort" but it is not yet beer. Water is "sparged" (or sprayed) though the grains to wash out as much of the extract as possible. The "spent grains" are removed and sold as cattle feed.

5.Boiling and Hopping

The brew kettle, a huge cauldron holding from 70 to 1,000 hectolitres and made of shiny copper or stainless steel, is probably the most striking sight in a brewery. It is fitted with coils or a jacketed bottom for steam heating and is designed to boil the wort under carefully-controlled conditions. Boiling, which usually lasts about two hours, serves to concentrate the wort to a desired specific gravity, to sterilize it and to obtain the desired extract from the hops. The hop resins contribute flavour, aroma and bitterness to the brew. Once the hops have flavoured the brew, they are removed. When applicable, highly-fermentable syrup may be added to the kettle. Undesirable protein substances that have survived the journey from the mash mixer are coagulated, leaving the wort clear.

6. Hop Separation and Cooling

After the beer has taken on the flavour of the hops, the wort then proceeds to the "hot wort tank". It is then cooled, usually in a simple-looking apparatus called a "plate cooler". As the wort and a coolant flow past each other on opposite sides of stainless steel plates, the temperature of the wort drops from boiling to about 10 to 15.5 °C, a drop of more than 65.6 °C, in a few seconds.

7. Fermentation

The wort is then moved to the fermenting vessels and yeast, the guarded central mystery of ancient brewer's art, is added. It is the yeast, which is a living, single-cell fungi, that breaks down the sugar in the wort to carbon dioxide and alcohol. It also adds many beer-flavouring components. There are many kinds of yeasts, but those used in making beer belong to the genus saccharomyces. The brewer uses two species of this genus. One yeast type, which rises to the top of the liquid at the completion of the fermentation process, is used in brewing ale and stout. The other, which drops to the bottom of the brewing vessel, is used in brewing lager.

In all modern breweries, elaborate precautions are taken to ensure that the yeast remains pure and unchanged. Through the use of pure yeast culture plants, a particular beer flavour can be maintained year after year. During fermentation, which lasts about seven to 10 days, the yeast may multiply six-fold and in the open-tank fermenters used for brewing ale, a creamy, frothy head may be seen on top of the brew. When the fermentation is complete, the yeast is removed. Now, for the first time ,the liquid is called beer.

8.Cellars

For one to three weeks, the beer is stored cold and then filtered once or twice before it is ready for bottling or "racking" into kegs.

9.Packaging

In the bottle shop of a brewery, returned empty bottles go through washers in which they receive a thorough cleaning. After washing, the bottles are inspected electronically and visually and pass on to the rotary filler. Some of these machines can fill up to 1,200 bottles per minute. A "crowning" machine, integrated with the filler, places caps on the bottles. The filled bottles may then pass through a "tunnel pasteurizer" (often 23 metres from end to end and able to hold 15,000 bottles) where the temperature of the beer is raised about 60 °C. for a sufficient length of time to provide biological stability, then cooled to room temperature.

Emerging from the pasteurizer, the bottles are inspected, labelled, placed in boxes, stacked on pallets and carried by lift truck to the warehousing areas to await shipment. Also in the bottle shop may be the canning lines, where beer is packaged in cans for shipment. Packaged beer may be heat-pasteurized or micro-filtered, providing a shelf-life of up to six months when properly stored. Draught beer, since it is normally sold and consumed within a few weeks, may not go through this process. The draught beer is placed in sterilized kegs ready for shipment.

1.Water

Pure water is an essential ingredient in good beer and brewers pay scrupulous attention to the source and purification of their brewing water. The water used in brewing is purified to rigidly-set standards. If it does not have the proper calcium or acidic content for maximum activity of the enzymes in the mash, it must be brought up to that standard.

2.Malt

Barley is used to make brewers' malt. At the malting companies, barley is soaked, germinated (sprouted), then dried and/or kilned/roasted to arrest further growth. During the period of controlled growth in the malting plant, specific barley enzymes are released to break down the membranes of the starch cells that make up most of the kernel. But these are internal changes only; apart from a slight change in colour, the external characteristics remain essentially unchanged. When the malt leaves a malting plant, it still looks like barley.

In the brewery, the malt is screened and crushed rather than ground to flour in order to keep the husks as whole as possible. This process not only prevents the extraction of undesirable materials from the husks but also allows them to act as a filter bed for separation of the liquid extract formed during mashing.

3.Mashing

Malt is added to heated, purified water and, through a carefully controlled time and temperature process, the malt enzymes break down the starch to sugar and the complex proteins of the malt to simpler nitrogen compounds. Mashing takes place in a large, round tank called a "mash mixer" or "mash tun" and requires careful temperature control. At this point, depending on the type of beer desired, the malt is supplemented by starch from other cereals such as corn, wheat or rice.

4.Lautering

The mash is transferred to a straining (or lautering) vessel which is usually cylindrical with a slotted false bottom two to five centimetres above the true bottom. The liquid extract drains through the false bottom and is run off to the brew kettle. This extract, a sugar solution, is called "wort" but it is not yet beer. Water is "sparged" (or sprayed) though the grains to wash out as much of the extract as possible. The "spent grains" are removed and sold as cattle feed.

5.Boiling and Hopping

The brew kettle, a huge cauldron holding from 70 to 1,000 hectolitres and made of shiny copper or stainless steel, is probably the most striking sight in a brewery. It is fitted with coils or a jacketed bottom for steam heating and is designed to boil the wort under carefully-controlled conditions. Boiling, which usually lasts about two hours, serves to concentrate the wort to a desired specific gravity, to sterilize it and to obtain the desired extract from the hops. The hop resins contribute flavour, aroma and bitterness to the brew. Once the hops have flavoured the brew, they are removed. When applicable, highly-fermentable syrup may be added to the kettle. Undesirable protein substances that have survived the journey from the mash mixer are coagulated, leaving the wort clear.

6. Hop Separation and Cooling

After the beer has taken on the flavour of the hops, the wort then proceeds to the "hot wort tank". It is then cooled, usually in a simple-looking apparatus called a "plate cooler". As the wort and a coolant flow past each other on opposite sides of stainless steel plates, the temperature of the wort drops from boiling to about 10 to 15.5 °C, a drop of more than 65.6 °C, in a few seconds.

7. Fermentation

The wort is then moved to the fermenting vessels and yeast, the guarded central mystery of ancient brewer's art, is added. It is the yeast, which is a living, single-cell fungi, that breaks down the sugar in the wort to carbon dioxide and alcohol. It also adds many beer-flavouring components. There are many kinds of yeasts, but those used in making beer belong to the genus saccharomyces. The brewer uses two species of this genus. One yeast type, which rises to the top of the liquid at the completion of the fermentation process, is used in brewing ale and stout. The other, which drops to the bottom of the brewing vessel, is used in brewing lager.

In all modern breweries, elaborate precautions are taken to ensure that the yeast remains pure and unchanged. Through the use of pure yeast culture plants, a particular beer flavour can be maintained year after year. During fermentation, which lasts about seven to 10 days, the yeast may multiply six-fold and in the open-tank fermenters used for brewing ale, a creamy, frothy head may be seen on top of the brew. When the fermentation is complete, the yeast is removed. Now, for the first time ,the liquid is called beer.

8.Cellars

For one to three weeks, the beer is stored cold and then filtered once or twice before it is ready for bottling or "racking" into kegs.

9.Packaging

In the bottle shop of a brewery, returned empty bottles go through washers in which they receive a thorough cleaning. After washing, the bottles are inspected electronically and visually and pass on to the rotary filler. Some of these machines can fill up to 1,200 bottles per minute. A "crowning" machine, integrated with the filler, places caps on the bottles. The filled bottles may then pass through a "tunnel pasteurizer" (often 23 metres from end to end and able to hold 15,000 bottles) where the temperature of the beer is raised about 60 °C. for a sufficient length of time to provide biological stability, then cooled to room temperature.

Emerging from the pasteurizer, the bottles are inspected, labelled, placed in boxes, stacked on pallets and carried by lift truck to the warehousing areas to await shipment. Also in the bottle shop may be the canning lines, where beer is packaged in cans for shipment. Packaged beer may be heat-pasteurized or micro-filtered, providing a shelf-life of up to six months when properly stored. Draught beer, since it is normally sold and consumed within a few weeks, may not go through this process. The draught beer is placed in sterilized kegs ready for shipment.

Subscribe to:

Comments (Atom)

Is consuming Wine daily good for health?

The idea of consuming wine daily, particularly red wine, has been a topic of interest for many years, with some studies suggesting potentia...

-

Pot stills and patent stills are two different types of distillation apparatus used in the production of alcoholic beverages, particularly...

-

The quality of service staff in any establishment reflects the quality of the establishment itself. No matter how good the food and ambien...

-

1) The table on which a tablecloth is to be spread, should be first covered with a baize base cloth, for the following reasons: a. To pro...